Luvis Steffan Kaushal

About Candidate

Dear Sir/ Madam,

Engineering opportunities

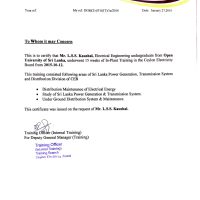

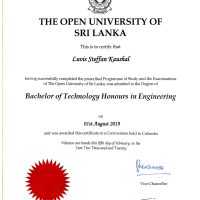

I am L. S. Kaushal, Currently working as Assistant Process Engineer at Ambewela Products (Pvt.) Ltd. Since November 4th January of 2020. But my working experience in here is nearly 6 years. Before current designation, I have worked as a production executive (technical) in this company. In that time of period I got a chance to sharpen my knowledge and skills in many ways regarding the industry such as Plant and Machinery maintenance, Planning and Designing, Repairing and Fabrication, Automation, Work management, documentation, Labour control…etc. In addition, I have successfully completed the B. Tech. (Hons) in Electrical Engineering Degree Program and an associate member of the IESL.

Passport Nationality

Passport No

Passport Issued Date

Passport Expiry Date

Passport Port Place of Issue

Passport Photo

1st Dose Name

1st Dose Date

Country

Licence No

Driving License Issued Country

Driving License Issue Date

Driving License Expiry Date

Location

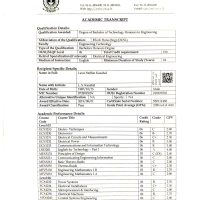

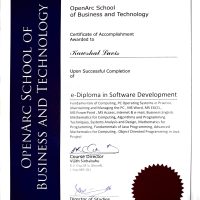

Education

Master of Energy Management

Bachelor of Technology Honors in Electrical Engineering

Diploma in Software Development

Mathematics Stream Index No. - 8041938 Combined Mathematics - S Physics - S Chemistry - S Z Score Marks +0.2397

Index No. - 33771944 Mathematics - A Social Studies & History - B Business & Acct. Studies - B Science & Technology - C Sinhala Lang. & Literature - C English - C Buddhism - C Art Subject - S

Work & Experience

Monitoring and responsible for smooth operation of whole process of the production/manufacturing chain and utility systems. Keep getting updated about dairy products processing machineries (All are fully automated), equipment’s and utility systems performance frequently. Planning and performing routine maintenance and repairs focusing on preventive scheduled maintenance of machineries (fully or partially automated) and utility systems of the plant. Performing maintenance requirement based on the priorities. Analyzing current operation status of equipment and utilities to predict and taking measures to prevent future failures to minimize the down time of the plant. Planning, Designing and fabricating automated or any kind of systems as per the requirement. Assisting to top management to optimize processes of the operation to achieving the maximum output. Preparing and handling related documents Updating machine breakdown records to identify and rectify natures of failures. Annual spare parts and consumable items records to maintain the inventory of required items related to services and repairs. Department related documents regarding outside services (Quotations, Service agreements, Service orders, Purchase orders, Purchase notes) Communications, negotiations, following ups. Communicate with outside service suppliers regarding necessary services (repairs, machinery services, materials, spare parts…etc.) of the factory. Negotiating with them to get better service and to reduce the cost for services as possible. Following up requested services to get the service done as soon as possible. Duties related to maintenance crew. Allocating crewmembers to relevant jobs. Monitoring the progress and giving instructions to do jobs. Keep monitoring and taking necessary actions to maintain the hygienic condition and disciplines of workers. Evaluating performance, experience, Neatness…etc.

Responsible for the quality of products. Keep monitoring and informing relevant responsible parties (quality department, engineering department, stores department) about issues and defects of products to maintain the quality of products always. Keep monitoring and taking necessary action to maintain the focus of workers toward the job they are doing and to maintain their hygiene condition. Keep monitoring and taking necessary action to keep the production environment clean, safe and to an order always. Managing production environment according to the daily production plan. Allocating required nos. of workers for relevant jobs according to the production plan given by top management. Getting materials from stores department for the day as per the production plan to avoid spacing issue, material damage…. etc. Department related document handling. Checking and comparing details of production log sheets with the physical quantities and parameters of the production process. Preparing and updating daily production report with the details of the production and dispatch summery. Preparing and updating machine breakdown records, job requisitions…etc. Handling stores department related documents (stores requisitions, GRNs, Purchase requisitions…etc.)

Inspecting and maintaining the electrical system and machineries of the factory. Design and Fabrication control panels for products. Repairing and Fault rectification. Inspecting the fabrication of products. Labor handling of the production.